As the offshore oil and gas industry continues to explore deeper and harsher marine environments, the demand for materials capable of withstanding both mechanical and corrosive stresses has never been higher. Alloy 625 (UNS N06625)—a nickel-chromium-molybdenum alloy—is widely adopted in subsea risers, manifolds, wellhead components, and flexible piping due to its exceptional resistance to corrosion fatigue. Unlike conventional stainless steels or low-alloy steels, Alloy 625 maintains mechanical integrity under cyclic loading in chloride-rich, high-pressure, and high-salinity environments.

This article explores the metallurgical mechanisms, fatigue behavior, and corrosion resistance that make Alloy 625 uniquely suited for offshore use, with specific attention to its performance under combined mechanical and chemical stress.

Alloy 625 has the following nominal composition (wt%):

| Element | Content |

|---|---|

| Nickel (Ni) | 58.0 min |

| Chromium (Cr) | 20–23 |

| Molybdenum (Mo) | 8–10 |

| Niobium + Tantalum (Nb + Ta) | 3.15–4.15 |

| Iron (Fe) | Balance |

| Others (Co, Ti, Al, Mn, C) | Trace |

Its superior performance stems from:

Solid solution strengthening from Mo and Nb.

Corrosion resistance from Cr and Mo.

A stable FCC γ-matrix microstructure without precipitation at grain boundaries.

Importantly, Alloy 625 does not rely on precipitation hardening, allowing it to maintain ductility even in aged conditions and after welding.

Corrosion fatigue is a complex interaction of:

Mechanical fatigue from cyclic loading.

Electrochemical attack that accelerates crack initiation and growth.

Synergistic damage that reduces fatigue life far below that in air.

In offshore systems, dynamic loading from waves, current-induced vibration, and pressure cycling create the mechanical stress. Seawater provides the corrosive medium, rich in chloride ions (Cl⁻), oxygen, and biofouling activity. The combination significantly reduces component lifespan.

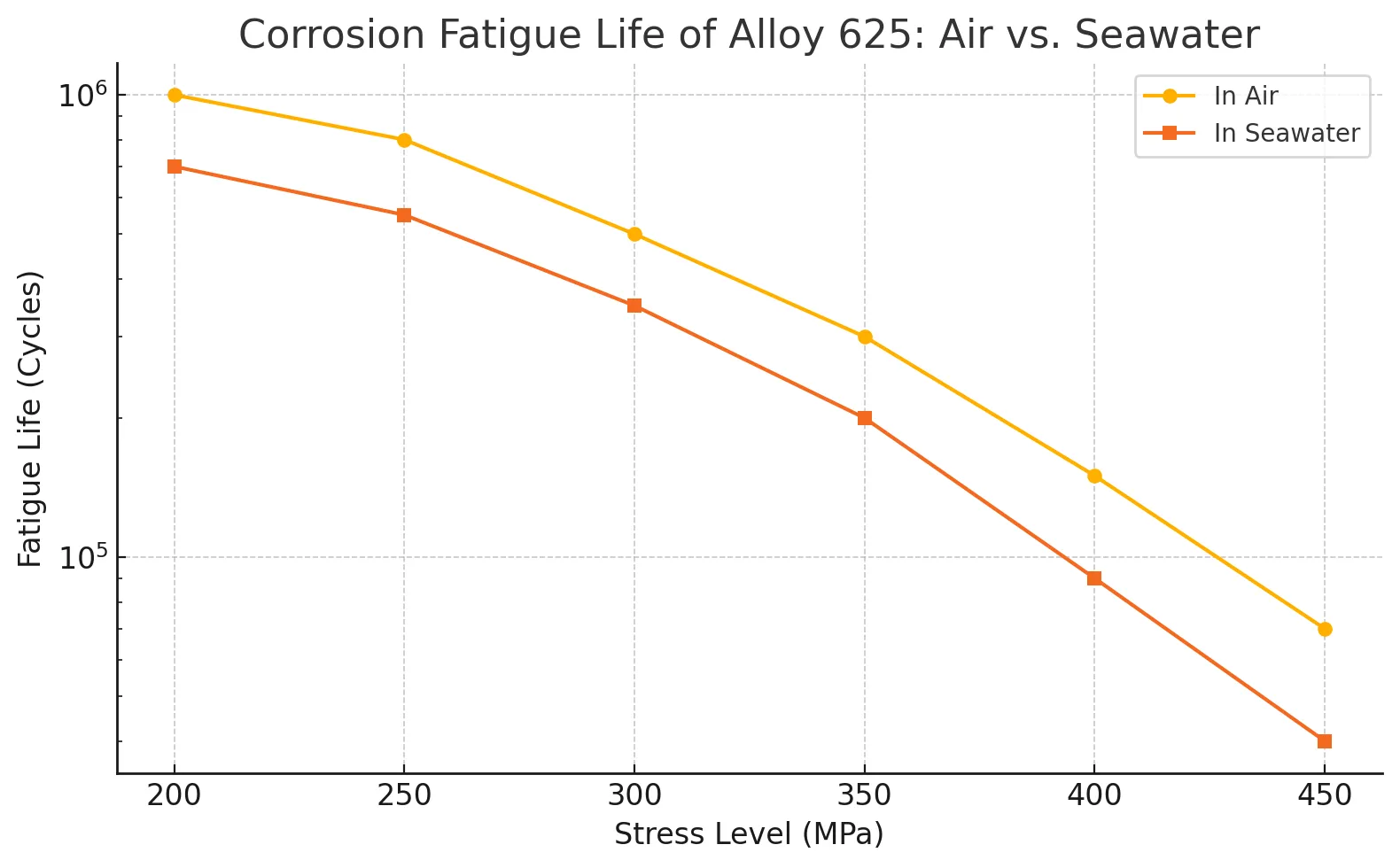

In laboratory tests, Alloy 625 was subjected to fully reversed axial loading at room temperature under two environments:

Air (neutral environment)

Artificial seawater (3.5% NaCl solution)

The results (as shown in the figure above) illustrate:

A logarithmic decrease in fatigue life with increasing stress.

Up to 30–40% reduction in cycles to failure in seawater compared to air at equivalent stress levels.

Example: At 400 MPa, fatigue life dropped from ~150,000 cycles in air to ~90,000 in seawater.

Such data confirms that Alloy 625, although highly resistant, still exhibits measurable fatigue degradation due to corrosion—but far less so than stainless steels.

Alloy 625's resistance to corrosion fatigue is rooted in:

Passivating oxide layer: Cr forms a dense Cr₂O₃ film that delays pitting.

Mo and Nb: Strengthen grain boundaries and improve resistance to crevice and localized corrosion.

Low carbon: Prevents sensitization and intergranular corrosion after welding.

Crack tip blunting: High ductility helps absorb localized strain and prevent crack propagation.

Furthermore, Nb-rich carbide precipitates (MC type) contribute to fatigue crack resistance by deflecting crack paths.

Alloy 625 is used in:

Flexible risers and jumpers: Subject to dynamic ocean loads.

Bellows and expansion joints: Where thermal and mechanical cycles combine.

Clad steel pipelines: Alloy 625 is metallurgically bonded as a corrosion-resistant inner layer.

Flanges, bolts, and connectors: Where both sealing and structural integrity are critical.

Field reports show that Alloy 625-based cladding systems can endure over 20 years of subsea service with minimal maintenance.

Unlike many high-performance alloys, Alloy 625 is readily weldable with processes like GTAW, SMAW, and GMAW. Key advantages include:

Minimal HAZ sensitization

Matching filler metals (ERNiCrMo-3) available

No post-weld heat treatment required in most cases

In fatigue testing, HAZ zones in Alloy 625 welds showed no early crack initiation, indicating high metallurgical stability even under marine conditions.

| Property | Alloy 625 | 316L SS | Duplex 2507 | Alloy C-276 |

|---|---|---|---|---|

| PREN (Pitting Resistance Eq. No.) | ~52 | ~25 | ~42 | ~74 |

| Fatigue Life in Seawater (at 400 MPa) | ~90k | ~15k | ~50k | ~110k |

| Weldability | Excellent | Excellent | Moderate | Good |

| Cost | High | Low | Medium | Very High |

While C-276 offers better pitting resistance, its high cost and reduced weldability make Alloy 625 more practical in most structural offshore roles.

Avoid sharp corners and stress concentrators in component design.

Use cathodic protection or coatings when galvanically coupled to carbon steel.

Allow for cyclic pressure testing margins in design codes (e.g., DNV-ST-F101).

Monitor fatigue damage via acoustic emission or phased-array UT during inspections.

Alloy 625 remains one of the most capable and versatile alloys for subsea oil and gas systems, particularly in environments where cyclic stress and aggressive corrosion coincide. Its high fatigue resistance, outstanding weldability, and long-term stability make it a preferred choice for engineers designing for the world’s most demanding marine conditions.

The combination of mechanical robustness and electrochemical integrity ensures that even as offshore operations grow deeper, more complex, and more environmentally sensitive, Alloy 625 continues to deliver on its promise of reliability and safety.

Tel: +86 0731 82250427

Tel: +86 0731 82250427 E-mail: sales@evernickel.com

E-mail: sales@evernickel.com phone: +86 17773160488

phone: +86 17773160488 Address: No.1 North, West Side of Xingda Avenue, Dainan Town, Xinghua City, Jiangsu, China

Address: No.1 North, West Side of Xingda Avenue, Dainan Town, Xinghua City, Jiangsu, China