In industries ranging from chemical processing and fertilizer production to oil refining and waste treatment, the need for materials that can withstand aggressive acid environments—especially sulfuric (H₂SO₄) and phosphoric (H₃PO₄) acids—is paramount. Alloy 28 (UNS N08028), an austenitic stainless alloy with high nickel and chromium content, offers outstanding resistance to both uniform and localized corrosion in these harsh environments.

Unlike conventional stainless steels or lower-grade nickel alloys, Alloy 28 provides superior pitting, crevice, and intergranular corrosion resistance, while maintaining excellent workability and weldability. This article explores the material’s performance mechanisms in acidic media, with a focus on process reliability in phosphoric/sulfuric acid systems, and includes corrosion rate data under varying concentrations.

Alloy 28 is designed with an optimized balance of alloying elements:

| Element | Content (wt%) |

|---|---|

| Nickel (Ni) | 30–32% |

| Chromium (Cr) | 26–28% |

| Molybdenum (Mo) | 3–4% |

| Copper (Cu) | 0.6–1.4% |

| Iron (Fe) | Balance |

| Carbon (C) | < 0.03% |

| Manganese, Si, Ti, N | Trace amounts |

Key metallurgical features include:

High Cr and Mo → Forms stable passive film, critical in chloride-containing acid systems.

Nickel content >30% → Enhances resistance to reducing acids and chloride SCC.

Low C and N → Reduces sensitization and intergranular attack post-welding.

This balance ensures Alloy 28 performs well in both oxidizing and reducing acidic environments—rare for a single alloy.

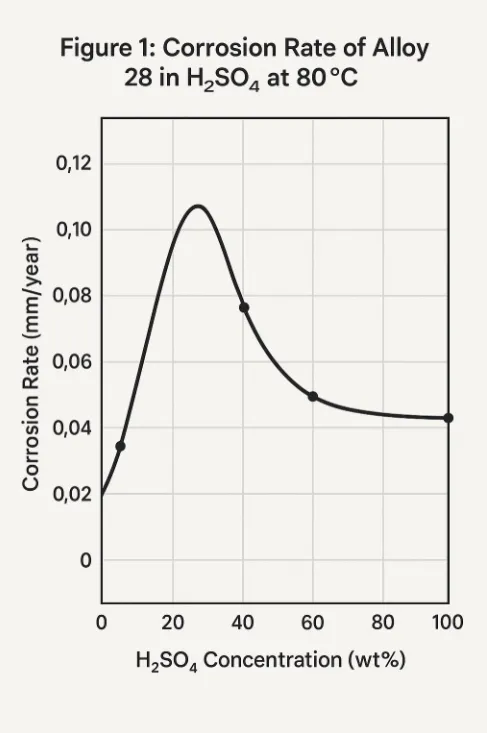

Sulfuric acid, especially in high concentration or contaminated forms, is one of the most corrosive industrial chemicals. Key observations:

Low-concentration (<20%) H₂SO₄ promotes general corrosion.

Mid-range (20–60%) often causes localized attack, especially under heat and stagnation.

High-concentration (>80%) creates passive behavior due to acid dehydration effects.

This passive behavior stems from the formation of a Cr-rich oxide layer, reinforced by Mo against pitting.

In phosphate fertilizer plants and wet-process phosphoric acid units:

H₃PO₄ is often contaminated with fluoride, chlorides, and suspended solids.

These conditions pose high SCC risk for low-grade stainless steel.

Alloy 28 has shown:

Negligible pitting or crevice attack in 30–50% H₃PO₄ at 70–90°C.

No SCC in long-term immersion tests (ASTM G36).

Excellent compatibility with evaporator, digester, and crystallizer equipment.

Moreover, Cu additions improve Alloy 28’s resistance in oxidizing-reducing mixed acid conditions, often encountered in multi-step fertilizer plants.

Unlike many high-performance alloys, Alloy 28 is:

Fully weldable using standard GTAW or SMAW techniques.

Compatible with filler metals like ERNiCrMo-3 or ERNiCrMo-10.

No post-weld heat treatment required in most service conditions.

Microscopy analysis of welded joints shows:

No carbide precipitation or grain boundary sensitization after welding.

Stable austenitic microstructure with uniform grain size distribution.

These features make Alloy 28 suitable for on-site repairs and custom-fabricated tanks and piping.

Alloy 28 is used in:

Evaporators, heat exchangers, and reactors in phosphoric acid plants.

Spent acid recovery units in sulfuric acid systems.

Heat transfer tubing in thermal acid environments (up to 120°C).

Piping, elbows, and valves in fertilizer slurries.

Case study: In a sulfuric acid alkylation unit, Alloy 28 tubes showed less than 0.05 mm/year corrosion rate after 3 years of operation, outperforming Alloy 316L and 904L under identical conditions.

| Property | Alloy 28 | 316L SS | 904L | Alloy C-276 |

|---|---|---|---|---|

| Ni Content (%) | ~31 | ~10 | ~25 | ~57 |

| PREN | ~42 | ~24 | ~35 | ~74 |

| H₂SO₄ Corrosion Resistance | Excellent | Poor | Moderate | Excellent |

| Phosphoric Acid Resistance | Excellent | Poor | Moderate | Excellent |

| Cost | Moderate | Low | Moderate | High |

Alloy 28 occupies the performance-cost sweet spot, offering superior resistance over standard stainless steels while being more economical than high-nickel superalloys like C-276.

While versatile, Alloy 28 has some limitations:

Not ideal above 300°C due to grain boundary diffusion risks.

Avoid stagnant zones to prevent crevice corrosion in chlorinated acids.

In environments with hydrofluoric acid or high chloride + oxidizer combinations, higher-alloyed options like C-22 may be needed.

Design tips:

Maintain fluid velocity >1.5 m/s in pipelines.

Use flanged joints with PTFE lining for improved sealing.

Apply electropolishing to internal surfaces to maximize passivity.

With growing emphasis on green fertilizer manufacturing, waste acid recycling, and critical mineral refining, Alloy 28 is expected to:

Expand into battery-grade phosphate production systems.

Be applied in sulfuric acid leaching of rare earth ores.

Be used in circular economy acid concentration plants with high impurity tolerance.

New developments include:

Fine-tuned microalloyed versions for even higher fluoride resistance.

Fabrication methods using explosion-bonded cladding over carbon steel to reduce cost.

Alloy 28 is a strategically engineered material that fills the gap between stainless steel and fully nickel-based corrosion alloys. Its localized corrosion resistance, especially in sulfuric and phosphoric acid environments, makes it ideal for the demanding conditions in fertilizer, chemical, and refining sectors.

Combining solid-state stability, fabrication ease, and long service life, Alloy 28 not only delivers cost-effective performance but also sets a standard for reliability in harsh industrial acid handling systems.

Tel: +86 0731 82250427

Tel: +86 0731 82250427 E-mail: sales@evernickel.com

E-mail: sales@evernickel.com phone: +86 17773160488

phone: +86 17773160488 Address: No.1 North, West Side of Xingda Avenue, Dainan Town, Xinghua City, Jiangsu, China

Address: No.1 North, West Side of Xingda Avenue, Dainan Town, Xinghua City, Jiangsu, China